Product

Here we highlight some of the label products offered by IL Pharma Packaging. Our products are renowned for their safety, utility and creativity.

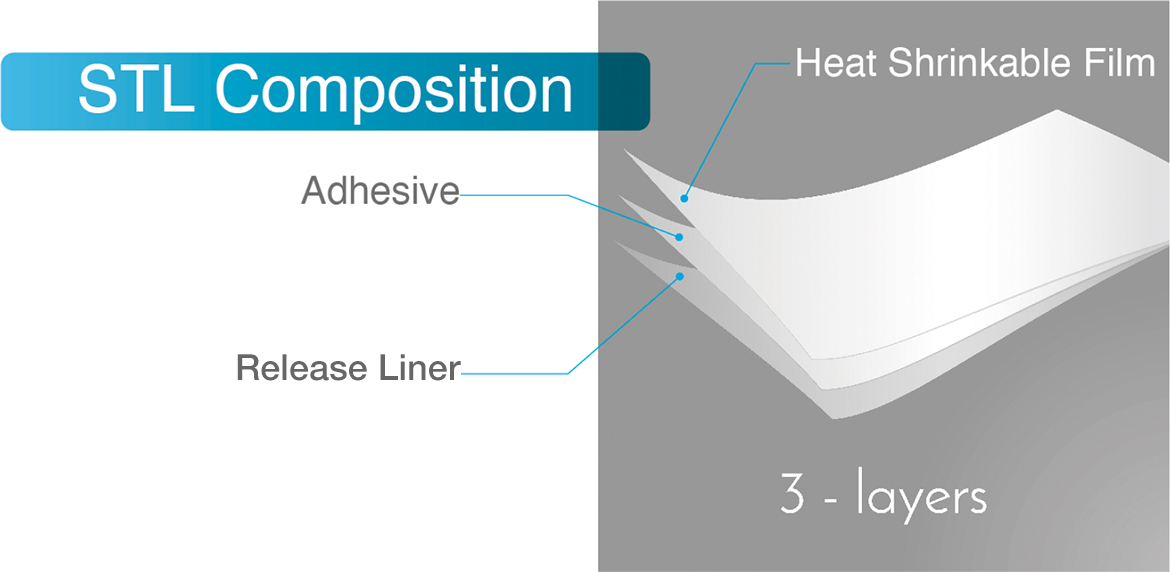

Shrink Tack Label - STL

A unique way of labeling and sealing solution in one process using a shrinkable film with adhesive at the back.

It is shrunk through heat with minimal heat exposure.

- Heat Shrinkable Label with pressure sensitive “adhesive” at the back

- Uniaxially extended film

| FEATURES | SLEEVE | STL |

|---|---|---|

| Less Heat Exposure | ||

| Pressure Sensitive Adhesive | ||

| Shatter Control / High Containment for Hazardous Drugs | ||

| Labeling and Sealing in One Machine (Small Footprint) | ||

| Requires Heat Tunnel |

← swipe →

| Surface base material | PET shrink | Thickness | 45μm Transparent / Amber | Thickness | 50μm Aluminum deposition |

|---|---|---|---|---|---|

| PE shrink | Thickness | 70μm | |||

| Adhesive | Acrylic | ||||

| Release paper | Polyethylene-laminated glassine paper or plastic film | ||||

← swipe →

Vial Protect

The protector and shrink tack label reduces risks of vial breaking and shattering. Users can also avoid coming into direct contact with hazardous residue on the vial surface.

Light Protect

By covering a vial with a shrink tack label, it can be equipped with light-protecting functions. Film options available to protect your light sensitive products.

Tamper Evidence

Tamper-evident labels provide visual evidence that the container has been tampered with or opened. Perforated label creates strong protection against tampering. Body area of the label stays on the bottle with adhesive.

Hanging Function

The Hanger Label offers labeling and hanging functions in one label at the possible lowest cost. The hanger part of the label can be easily folded back when use. The Hanger Label could be applied by your existing vial labeling machine.

Medication Error Prevention

By removing and re-attaching the tab part to a syringe, the risk of mix-up and medication errors can be reduced.

Cryogenic Label

Withstands storage in liquid nitrogen and ultra-low temperature freezers.

Environmental products

Sustainable products are not just products, they are investments in the future. Our combination of state-of-the-art technology and environmental leadership provides our customers with valuable products, while at the same time having a positive impact on the planet.

Biomass Vial Protect Pack II

We offer materials manufactured using plant-derived resources as part of the raw materials for the resin protector of the vial protector pack.

FSC® / COC Certificate

FSC®/COC certification allows us to offer earth-friendly adhesive labels and paper products with the FSC® certification mark, which are made from raw materials from properly managed FSC® certified forests and other controlled sources.

Biomass Ink

These inks are manufactured using plant-derived resources as part of the raw materials, and can contribute to reducing CO2 emissions and the use of petroleum resources.

Recycled PET Materials

We offer materials that use 100% recycled PET resin for the surface base material. Available in transparent and white.

Thin Film Label

Thinner surface base material and backing paper reduce the amount of waste. Since the weight is reduced, CO2 emissions during transportation are also reduced.

Vial Protect Pack I

Features

- By covering the vial with a plastic bottom protector plate and a shrink tack label, the risk of the vial breaking and shattering is reduced.

- As the vial is covered from the aluminum stopper to the base protector with a shrink tack label, even if the vial breaks, the contents are prevented from spilling.

- Attachment of the protector and application of the shrink tack label can be performed with a single labeler unit.

Vial Protect Pack II

Features

- As plastic cup (protector) and shrink tack label cover the vial, it provides extra durability against breakage. Users can also avoid direct contact to the hazardous residue on the vial surface during handling.

- Even if the vial breaks, the contents are prevented from spilling.

- The container and protector are held in place with an adhesive, eliminating any worry of the vial slipping out of the protector.

- As the packaging fits closely against the vial, there is almost no change in its shape or size, making it easy to handle in a medical setting.

- This can also be applied using a conventional shrink tack labeler.

- US9592950 EP2937292

Related Links

Shrink Tack Label - Light Protection

Features

- Light resistance can be achieved from UV light to visible light range. Film options available.

- Applications and shrinking is done in one labeling machine.

- Due to perforation, the cap can be easily opened simply by lifting, and confirmation of the content liquid is possible. (Windowless types without removable labels are also available)

Shrink Tack Label - For Eye Dropper

Features

- Labeling and sealing in one process.

- Pre-shrinking is not required.

- Even after the cap area of the label is removed, the body part stays on the bottle with adhesive.

- With uniaxial oriented material, there is little distortion of the barcode.

Shrink Tack Label - For Syringe

Features

- Labeling and sealing in one process.

- Turn the rubber cap to open before use. Traces of opening may be left on the label.

- Depending on the shape or size of syringes, sealing options available.

Hanger Label

Features

- A hanger and label all in one.

- The hole in the label allows easier flip.

- Low cost. Your existing labeling machine could be used.

- Compared to a plastic hanger, it is easier to sort waste out and generates less waste.

- The hanger allows easy distinction between IV and injection drug bottle.

Transferable Label

Features

- After the medications has been drawn up out of the ampoule with a syringe, a tab part of the label is peeled off and transferred to the syringe. This could prevent medication mix-up or errors.

- When medication has been coinjected into an infusion bag, peeling off a portion of the label and applying it to the bag can prevent staff from forgetting or duplicating coinjection.

- The solution does not require extra investment and in most cases, your existing labeling machine can be used.

Related Links

Cryogenic Label

Features

- The in-house test shows that the label firmly dtays on the glass vial in liquid nitrogen.

- Even after the thawing process, the label adhesion does not change.

- * Test results are not guaranteed.

Click here to download our company brochure.

IL Pharma Packaging PDF(2.24Mb)